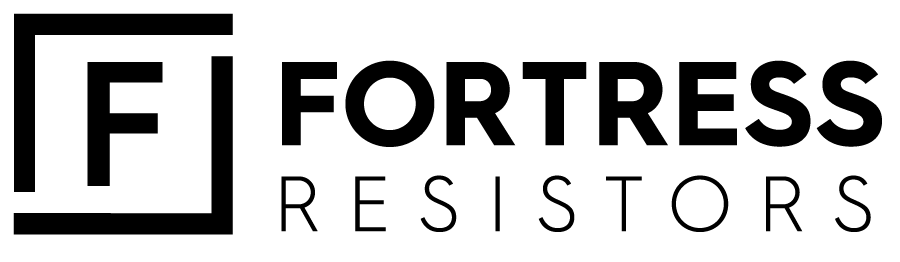

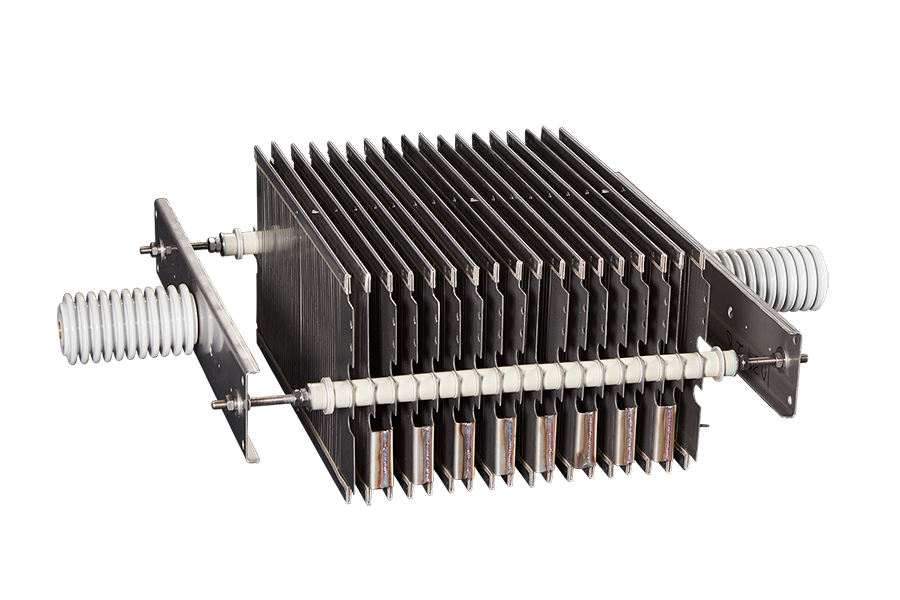

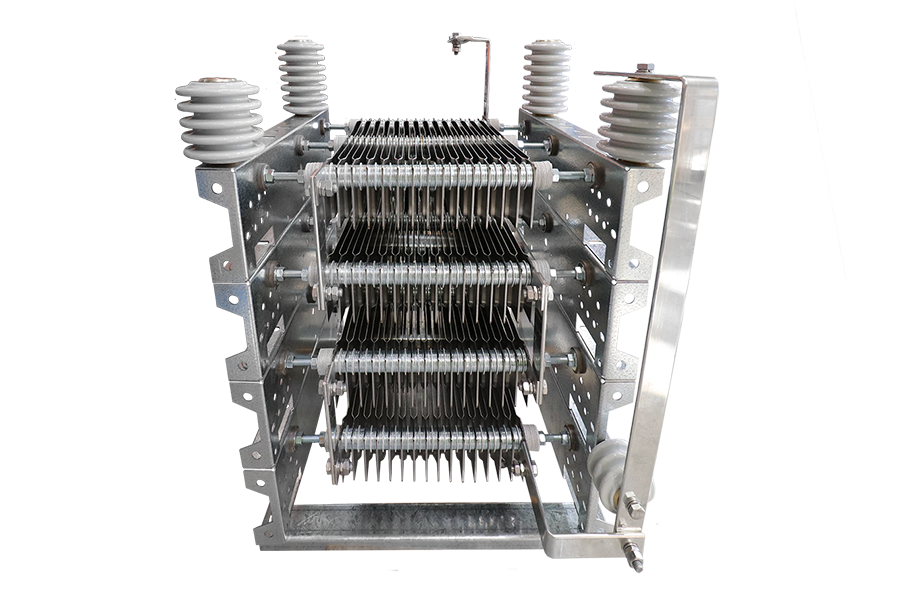

Filter Resistors

The ever-increasing use of power electronics and other solid state devices, which generate harmonic voltages, make the use of filter resistors and issue of power quality more and more important both for suppliers and users of electrical power.

Complex waveforms created by solid-state devices in power system converters, motor controls, etc. feed harmonics into power systems, causing trouble with equipment connected elsewhere in the system.

The solution is higher order harmonic filters consisting of capacitors, inductors and resistors tuned to eliminate specific frequencies. The capacitors and inductors allow the fundamental frequency through and divert the harmonics into the filter resistor where the harmonic currents are dissipated as heat and thus lost from the system.

Fortress Resistors, often in partnership with Post Glover or other group companies, design, build and test filter resistors in accordance with applicable IEC and IEEE standards to guarantee their performance. With no two installations ever being the same, our experienced engineers develop the proper solution for your particular application and environment. Our low inductance designs are built using all stainless steel elements in corrosion resistant enclosures chosen for your unique specification. Post Glover’s reputation in filter resistors has been built on over 100 years of field performance and independent test facilities, where they have proven their engineering and manufacturing prowess to be second to none.

Design Considerations

Power Dissipation

This power is partially stored in the mass of the resistor elements before being transferred to the surrounding environment through convection cooling. Not only is the overall mass of the current carrying material important, but also:

- The surface area of the resistor elements

- The temperature difference between ambient air and the heating elements

- The cumulative effect of the resistors on each other

Resistance Value

The overall filter design dictates the required resistance. As such, it is imperative the ustomer specify the nominal value of the resistor as well the desired tolerance.

Additionally, the inherent inductance of the resistor may affect the performance of the filter. Fortress engineers their resistor assemblies to not only minimize this inductance, but also limit the change in resistance as the elements heat up to guarantee a stable operating profile.

Voltage/Insulation

The resistor must be designed in accordance with local standards (IEEE, IEC, etc.) and consider line to line voltage, arcing distances, creepage distances, BIL withstand level and any expected voltage transients.

Current Rating

The resistive elements, along with the internal and external connections must be carefully considered and engineered to carry not only the rated current, but also periodic high current transients.

Miscellaneous

Other factors can contribute to the design of the resistor, including physical conditions of the site such as the level of atmospheric pollution, seismic zone, corrosive environment, wind and altitude.

The Fortress Difference

Fortress Resistors has a history of successfully managing large projects and provides value to customers by ensuring we understand the customer's requirements and expectations. We place an equal importance on technical capability, manufacturing to deadlines, and providing documentation and drawings in a concise and timely manner.

Not sure what you're looking for?

Fortress Resistors offer a wide range of products and services and are happy to provide advice to assist you to make the right decisions for your application. If you need help adapting a product to suit your needs, advice on complying with applicable standards, or if you can’t find the information you’re looking for, send us an enquiry or give us a call. One of our team will get back to you promptly.